Suspension - wheels - tyres

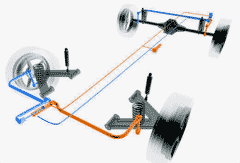

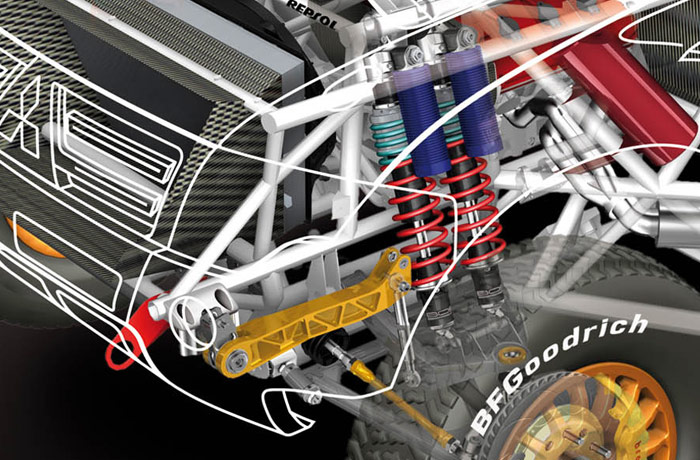

Every wheel has a double wishbone suspension with stabilizer bars front and rear. Two compact coilovers are linked from the upper wishbone to the frame and each has a separate gas reservoir. Rules dictate a maximum wheel travel of 250mm front / rear. In previous years an advanced system with interlinked stabilizer bars from Kinetic was successfully used but for 2007 it is banned.

The wheels are made from aluminum alloy their size is 7x16" and the tires are from BF Goodrich 235/85-16. The rules allow only one tire type to be used during the race so the only thing the teams can do to adjust to every kind of terrain is to vary the tire pressure. During the previous races many cars used systems that allowed them to vary the pressure from inside the car and in the move. These systems are also banned this year and the crew has to get out of the car to increase / decrease tire pressure which apart from the time lost may lead to a tire destruction or even an accident if the crew forget to re-adjust the tires The pressure span is very big, from 3 bar used in rocky terrain to 1.6 bar in sand dunes.

Aerodynamics

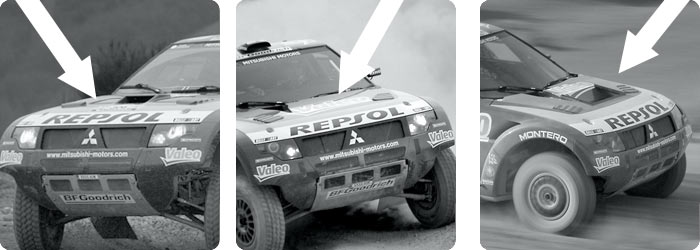

It may be very short and tall but the MPR13 like its predecessors is extensively studied in a wind tunnel in order to be stable enough to travel fast (~200kmh) over rough terrain.

The work that is made in aerodynamics and heat transfer is shown from the various bonnet versions that have been tried and tested for the 2007 racing Pajero. The chosen one is the design on the left photo below with the small air intake. The other two photos, with no air intakes and with the big airflow opening, are from tests before 2007 Dakar.