Fuel quality depends on many factors but as a commercial product, gasoline is judged mainly (even only) from octane-rating. But what exactly is the meaning behind that number and what is its use?

Octane rating is a conventional measure that shows how much a fuel mix can be compressed without self-ignite. Iso-octane has very good resistance to auto-ignition and n-heptane on the contrary ignites easily when compressed. The octane rating of a gasoline fuel is the ratio of a mix consisting of iso-octane and n-heptane in such analogy in order the mix and the respected gasoline fuel to have exactly the same resistance in auto ignition when compressed (the auto-ignite at the same pressure).

For example, 95 octane gasoline has the same resistance to self-ignition as a mix of 95% octane and 5% heptane.

But why do we need fuel with high resistance to self-ignition under pressure? The answer is simple, the efficiency of the engine depends of the compression ratio, thus how much the air-fuel mix will be compressed before the ignition. If in a given engine we use gasoline with lower octane rating than necessary we will cause a lot of damage. Not only the fuel-air mix will ignite early but also that ignition is sudden and uncontrollable. There will be multiple flame fronts and sudden pressure spikes instead of a controlled ignition that we normally have with spark plug.

The main parameters that dictates what kind of fuel is suitable for every engine are three, the geometric compression ratio, the electronic fuel and ignition management and the existence or not of a supercharger.

1).The geometric compression ratio is defined from the ratio of the cylinder volume with the piston at the TDC to the cylinder volume with the piston at the BDC. The geometric compression ratio is fixed for a given engine and can only be change with mechanical alterations (ex piston change).

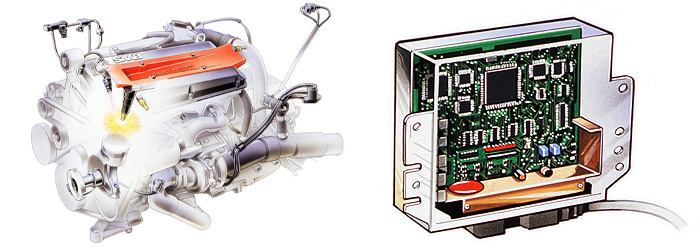

2).The electronic fuel and ignition management is a more complicated matter.

In a piston engine theoretically the ignition should take place when the piston crown reaches the TDC. If the fuel-air mix ignites earlier the exhaust gases will provide a resistance at the -still going upwards- piston, if it ignites after the TDC pressure potential is wasted during the distance that the piston has already travel downwards.

(engine with separate ignition coil per cylinder and advanced electronic ignition management - photo SAAB)

(engine with separate ignition coil per cylinder and advanced electronic ignition management - photo SAAB)

The world, 'theoritically' we used in the previous paragraph is very important. It implies that combustion occurs instantly in zero time, which may be almost the case in very low revving engines but the usual car and motorcycle engines behave differently. The optimum timing for ignition is to take place without decelerate the ascend of the piston to TDC and without waste downward piston travel (after the TDC) and energy.

The fuel-air mix needs a certain time to fully combust and the available time the piston stays around the TDC decreases the more the engine spins in higher revs. The optimum ignition time is the one that will give the maximum gas pressure when the piston is in the TDC, thus in high revs the ignition must start when the piston is still ascending to give time for the pressure to build up until it reach the TDC. The adjusting mechanism of the optimum ignition timing is called 'Timing advance' and in modern cars and bikes is electronically controlled from the electronic ignition.

If the electronic ignition is advanced and there also is a knock sensor an engine even if it is set up to use 98-octane fuel can also operate safely with slightly lower octane rating gasoline. In that case the ignition takes place earlier during the ascend of the piston. That may reduce the efficiency and the power of the engine but it also prevents fuel mix self-ignition and engine wear. Contemporary engines can tolerate lower octane fuel or take advantage of high-octane fuel to a point.

In reality even a very advanced electronic ignition can do much by itself. A normally aspirated car with indirect fuel injection has almost insignificant power benefit from higher-octane fuel that borders in the statistic error when measured in a dynamometer. A high-revving motorcycle engine with a high compression ratio may have some benefit but small nonetheless.

One can tune an engine to exploit high-octane gasoline and thus be more efficient and powerful but then the use of regular 95-octane unleaded may damage it.

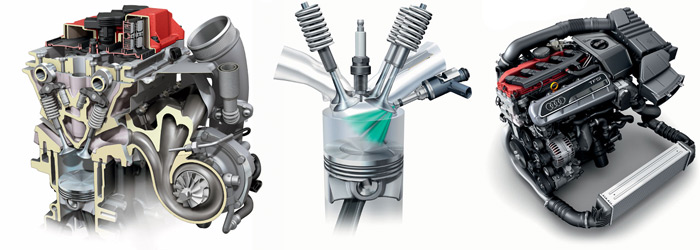

Direct injection with pilot fuel injection, multi-phase injection and stratified charge have more ways to exploit a better fuel and even if they are tuned for high-octane fuel use are very flexible with normal gasoline. Dynamometer tests show a detectable and sometimes significant benefit from high-octane fuel use in those engines.

3).Supercharging.In non-normally aspirated engines the maximum fuel-air mix compression is dictated by the existence of the turbocharger(s), supercharger (or both if that's the case). The supercharging system's flow adds to the total mass of the air-fuel mix that is entering the cylinder. Although the geometric compression ratio is fixed, the fuel-air mix is subjected to higher pressure (relatively to a N/A engine) because it was already under pressure when initially entering the cylinder. The resulting compression ratio is relative to the flow of the supercharging system and can reach much higher values than the geometric compression ratio of the engine.

(direct injection engine with exhaust turbo from Audi TT RS - photo Audi)

(direct injection engine with exhaust turbo from Audi TT RS - photo Audi)

Depending to how advanced the supercharger system management is (with the use of by-pass, pressure valves etc) and of course in cooperation with the electronic fuel and ignition management and the injection system, an engine can have substantial benefits from the use of high-octane petrol. If all those parameters and system work correctly an engine can be very flexible (much more than a regular indirect injection engine). It can regulate the pressure inside the cylinder at every given time in order to work safely and efficiently with regular fuel and have power and efficiency advantages from high-octane fuel.

Comparative dyno tests with regular and high-octane gasoline in engines with advanced supercharging and direct injection show significant increase in power and those cars are probably the only road cars (at least in stock form) that the use of this more expensive fuel is meaningful.

Conclusions for the use of high-octane fuel:

As we can deduce from the above every engine has an octane-rating span that can operate safely or benefit from the fuel. For example a car that its maker suggest the use of 95-octane gasoline can operate safely with 91-octane fuel (with lower octane rating it will break down eventually) and can exploit fuel of up to 98 octane-rating with some actual benefit (more and there will be no diffirence). The 91-98 span is of course an example, we don't suggest that any 95-octane rated car can operate safely with 91 ron fuel or have any advantages with 98.

Most car/bike makers focus this span towards safety thus most engine can work safely with lower quality fuel instead of being able to exploit more expensive gasoline.

It is worth mentioning that apart from octane rating this 'premium' fuel is usually of a higher quality or have improvement add-ons. Some brands distill their premium fuel separately and distribute it as a closed product. If you only use this petrol you may reduce the chances of using bad quality gasoline or benefit your car from the higher overhaul quality of the gasoline even without any power increase. However those things are extremely hard to measure and most of the times hardly worth the extra cost.

In some cases users have report a decrease in fuel consumption with the use of higher-octane petrol. The only way that can be occur is the increase of the engine power that for a given power requirement from the driver leads to milder use of the gas pedal and finally lower fuel consumption. Even without any power increase, the possibly higher quality fuel can have a similar effect. Other users report increase in fuel consumption but this has more to do with psychology (the car is most powerful so I can go faster etc). In most cases the power benefit is zero or insignificant and even if it is actually there one should justify a slightly lower fuel consumption (ex -0.5%) with the higher price of the fuel (ex +20%).

As a final conclusion we can say that if you have a normal family car chances are there is zero benefit from using high-octane fuel. If you have a powerful motorcycle or a direct injected car you may see a small power increase, but the only cars that the use of such fuel has any significant effect are super/turbocharged cars with advanced engine management or specially tuned ones.