This could very well be the future of automotive industry. What started with a small sportscar of great potential but narrow appeal, the Tesla Roadster, which was made largely from subcontractors, now is forming to be a major automotive player with a fully integrated R&D and production process. Tesla motors (like its cousin Space X) applied Silicon Valley principals to a saturated and unwieldy sector and by introducing next year the new upper mid-class sized Model S is now directly competing the mainstream auto companies exclusively with zero emission electric vehicles.---

Tesla as a new company doesn’t have the design tradition or an existing family look for their cars. This is just the second model of its brief history and it follows along the lines of the first. The Roadster was build by Lotus over a modified Elise platform and its design was simple and uncluttered. Tesla chief designer, Frank Von Holzhausen (involved on the noticeable Pontiac Solstice and Mazda Furai) followed the same path. Model S is simple but not primitive, it has great proportions, lack of meaningless decorative elements (a very wide-spread disease in contemporary car design) and great attention to detail. Apart from the mostly fake front grill, the design is echoing the underlying structure and purpose of the car. The result is a restrained but distinct and contemporary look, fit for a very innovative car which aspires to become mainstream without alienating its customers too much. Aerodynamics is very important, not only for efficiency but also for stability. The Model S has even or rear-biased weight distribution and aerodynamic stability is crucial. Tesla amongst other engineering talent has recruited ex-F1engineers to work on Model S shape. Vehicle dynamics are also of great value. The suspension is state of the art with double wishbones at the front and a multilink arrangement in the back. Suspension components are made from cast or extruded aluminum parts and are designed in-house specifically for Model S. Partners are big household names like Brembo or Bilstein and experienced engineers (originated from established companies like Lotus or Ford) work on the final set-up.

The interior follows the same design philosophy. Tesla leapfrogged the trend of continuously growing infotainment screens and incorporated a huge 17’ touchscreen in the center console. This not only incorporates all the necessary functions, from HVAC to music and navigation, but along with the smaller screen in front of the driver provide the necessary space for future upgrades (currently it uses a Linux based software) and other applications. Components like an air-vent or a button however small, have a disproportional expensive development cost. Tesla sourced some of them from its partners Mercedes Benz and Toyota or other common specialized manufacturers.

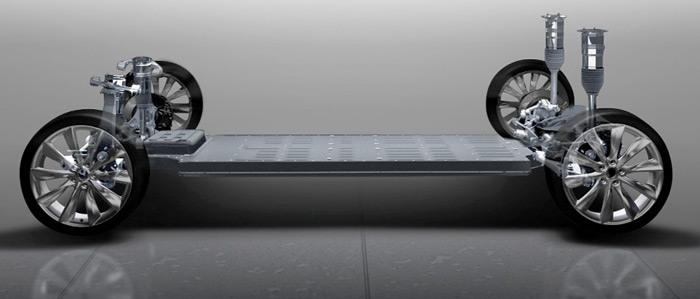

The propulsion is of course the raison d’etre of Tesla and as expected Model S is a fully electric vehicle. The electric motor along with the gearbox and power electronics form the transaxle, which is placed inside the rear suspension’s subframe. As usual with Tesla, both the motor and the batteries are liquid cooled. The electronically controlled cooling system closely monitors the temperature of the batteries in order to operate them at their peak efficiency. It is a complicated and expensive solution compared to the simpler air-cooled drivetrains (like the one on Nissan Leaf) but it appears to yield the best results. The batteries are packaged in a very thin flat pack underneath the passenger cabin. Initially the Model S will be available with a similar sized battery to the one fitted in Roadster (around 53kWh). However instead of the 120Wh/kg battery pack of Roadster the Model S will be more efficient and it will at least match the 135Wh/kg of the electric Smart (developed by Tesla). Improvements like that provide the larger and heavier Model S with the same range of the Roadster. A high performance pack will also be available as an option. It will have a 85kWh battery pack, 320miles range and it will be faster, needing only 4.5” to reach 100kmh.

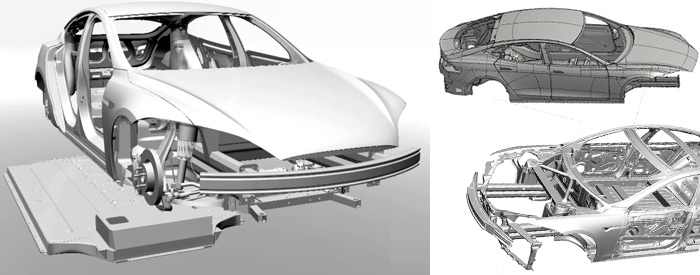

Model S is designed from a clean sheet of paper without any compromises that come when a vehicle needs (or needed) to accommodate an internal combustion engine. Its frame is almost entirely made from aluminum (98% by weight) and it is comprised from castings and extrusions along with some stamped parts (where loads are relatively light) all welded together to form a very rigid structure. The compact and favorable packaging of the drivetrain not only allows for optimum loadpaths and triangulation of the frame but also the battery pack is an actively stressed member of the chassis. By itself it has the rigidity of a sportscar’s frame and when installed the Model S becomes 3 times as rigid. The result is what appears to be a class leading design, with weight close to that of the similarly sized and usually slower petrol or diesel cars of the competition (ex BMW 550i, Lexus GS450h or Audi A8) at around 1800~1900 kg despite the weight of the batteries.

Tesla as a producer of a niche premium product, the 100k Roadster, was hit by the 2008 (and on) economic crisis. However the major reform of US automotive industry produced a big opportunity. The NUMMI plant in Fremont California, build over a 60’s GM plant by a consortium of GM and Toyota in 1984 was bought by Tesla at a ridiculous for pre-2008 economy cost. Apart from that, Toyota is also Tesla’s partner, they use Tesla’s drivetrain for electric vehicles (like the latest RAV4EV) and this partnership is growing from a couple hundred million dollars business closer to a billion or even more.

Tesla has already produced 20 prototypes of Model S (“Alpha”) with their bodies made by a subcontractor in Michigan. The next 50 (beta?) are currently under production at Fremont and they will be used for evaluation and tests. The first customer deliveries are planned for mid-2012 with a 5000 production for this first year. Later on production will reach 20.000 per year. As Elon Musk stated, they started with a high-cost, low volume product (the roadster), they now continue with a mid-cost, mid-volume (the S) and later on they will enrich the lineup with low-cost, high-volume products and more upmarket models like a roadster replacement sports car.

You can find more info at teslamotors.com and at these three videos where chief engineer Peter Rawlinson explain some of the basic concepts of Model S : Part 1 , Part 2 , Part 3